TRAX at Peacock's Recycling : Born for recycling

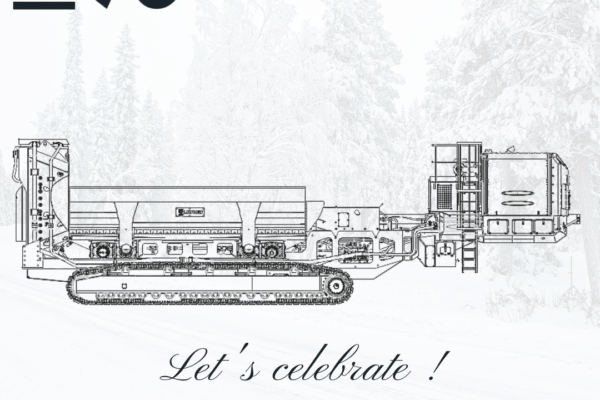

Peacock’s Recycling of Macon, GA USA, have been using their first LEFORT® TRAX 650 (660 US tons) since 2022. This unique shear/baler/logger on tracks was invented and internationally patented by LEFORT®. Here is Eddie Peacock’s testimonial.

LEFORT® AMERICA : Eddie, how long has Peacock’s Recycling been in business? Can you give us a little history?

EP : We’ve been in business legally since about 1980 and the other business started about 1976 and I’ve been cutting up cars and junk since 1959, when I was 8 years old. Been doing it a while had a chop axe and a hammer to cut them up with and a box of matches so we could burn them. We had to burn them back then and cut them in four pieces. This business has pretty good things after coming from that.

LA : What drove your decision to buy your LEFORT® ?

EP : The old machinery I had wouldn’t work and was constantly breaking down. We looked at LEFORT®, watched them work and were immediately interested. They worked good, and everybody I talked to was very satisfied, so we tried one. We’ve had it for just over two years,

and it’s been a real good machine. We’ve had a few simple problems with it, but the technical staff at LEFORT® AMERICA have always been there and solved them. They’ve never let us down. We’re completely satisfied with the machine.

LA : How has owning LEFORT® impacted your business?

EP : We had a fairly new machine that wouldn’t run two days a week barely and then it was down for about a year or better and didn’t run at all. I absolutely had to do something to modernize my tool. That’s when I met LEFORT®. If I hadn’t bought this machine, we’d probably be out of business. We needed a reliable machine. Today, with the LEFORT®, we process 500-600 tons a month of cut grade average usually, 100 tons of 1 ½ bundles and 1,000 tons of shred on the low end.

LA : What do you think of the quality, design and construction of your LEFORT® ?

EP : LEFORT®’s engineers are the best I’ve ever met. Our machine is stable and robust. There is very little downtime. The machine doesn’t wiggle, move, bulge, it just sits and works. It doesn’t twist, bind or anything. It’s a good machine.

LA : As your business grows, would you buy another LEFORT® in the future?

EP : I’ll be buying another one in the near future. They’re great machines. The price point and support. Everyone I’ve dealt with is knowledgeable, friendly, receptive to our needs and open to suggestions about changes for our specific needs.

Des questions ?

Contactez nous